Serialized inventory management software offers businesses a powerful tool for precise tracking and control of individual items. This sophisticated approach goes beyond simple quantity counts, providing detailed histories for each unique product. Understanding the benefits and implementation of serialized inventory management is crucial for businesses seeking to optimize efficiency, reduce losses, and enhance overall supply chain visibility. This enhanced level of control leads to better decision-making and improved profitability.

Source: cloudinary.net

The ability to trace individual products throughout their lifecycle – from manufacturing to final sale – offers unparalleled insights. This detailed tracking allows businesses to identify and address issues promptly, minimizing waste and maximizing resource utilization. Moreover, serialized inventory management software facilitates compliance with industry regulations and enhances overall operational transparency.

Source: altexsoft.com

In today’s dynamic business environment, efficient inventory management is paramount. For businesses dealing with high-value, unique, or easily counterfeited goods, serialized inventory management software offers a robust solution. This comprehensive guide delves into the intricacies of serialized inventory management, exploring its benefits, functionalities, implementation, and best practices. We’ll also address frequently asked questions to provide a complete understanding of this crucial aspect of supply chain optimization.

Understanding Serialized Inventory Management: Serialized Inventory Management Software

Serialized inventory management involves tracking individual items within your inventory using unique serial numbers. Unlike batch or lot tracking, which groups similar items, serialization provides granular visibility into each product’s journey, from manufacturing to the end customer. This level of detail is critical for industries with stringent regulatory requirements, high-value goods, or a need for robust anti-counterfeiting measures.

Benefits of Serialized Inventory Management Software

- Enhanced Security and Anti-Counterfeiting: Serialization makes it significantly harder to counterfeit products or introduce unauthorized goods into the supply chain. Each unique serial number can be verified against a central database, confirming authenticity.

- Improved Traceability and Recall Management: In the event of a product recall, serialized data allows for quick and precise identification of affected items, minimizing losses and protecting consumers.

- Reduced Inventory Shrinkage: Accurate tracking minimizes discrepancies between physical inventory and recorded stock levels, reducing losses due to theft, damage, or misplacement.

- Streamlined Supply Chain Operations: Real-time visibility into inventory levels and movements optimizes supply chain processes, leading to improved efficiency and reduced costs.

- Better Inventory Control and Planning: Detailed data enables more accurate demand forecasting and inventory planning, minimizing stockouts and overstocking.

- Compliance with Regulations: Many industries, including pharmaceuticals, medical devices, and electronics, require serialized inventory tracking to meet regulatory compliance standards (e.g., the Drug Supply Chain Security Act (DSCSA) in the US).

Key Features of Serialized Inventory Management Software

Effective serialized inventory management software incorporates several key features:

Core Functionalities:

- Serial Number Generation and Assignment: The software should automate the generation and assignment of unique serial numbers to each item.

- Real-time Tracking: Provides up-to-the-minute visibility into the location and status of each serialized item throughout the supply chain.

- Integration with Other Systems: Seamless integration with ERP, WMS, and other enterprise systems is crucial for a holistic view of inventory data.

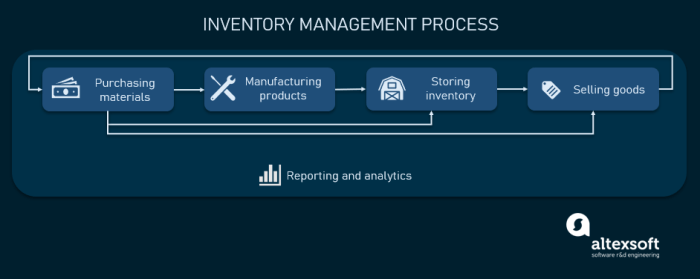

- Reporting and Analytics: Comprehensive reporting capabilities allow for detailed analysis of inventory trends, performance metrics, and potential areas for improvement.

- Data Security and Access Control: Robust security measures are essential to protect sensitive inventory data from unauthorized access.

- Barcode and RFID Integration: Supports integration with barcode and RFID technologies for efficient data capture and tracking.

- Audit Trails: Maintain detailed audit trails of all inventory transactions to ensure data integrity and compliance.

- Mobile Accessibility: Provides mobile access to inventory data for on-the-go tracking and management.

Implementing Serialized Inventory Management Software

Implementing serialized inventory management software requires careful planning and execution. Consider these steps:

Implementation Steps:

- Needs Assessment: Define your specific inventory management needs and challenges to select the right software solution.

- Software Selection: Evaluate different software options based on features, scalability, cost, and integration capabilities.

- Data Migration: Migrate existing inventory data to the new system accurately and efficiently.

- Training and Support: Provide adequate training to your staff on using the new software and ensure ongoing support is available.

- Testing and Validation: Thoroughly test the software to ensure accuracy and identify any potential issues before full deployment.

- Ongoing Monitoring and Optimization: Continuously monitor system performance and make adjustments as needed to optimize efficiency.

Choosing the Right Serialized Inventory Management Software

Selecting the appropriate software is crucial for success. Consider factors like:

- Scalability: Ensure the software can handle your current and future inventory volume.

- Integration Capabilities: Check for seamless integration with your existing systems.

- User-Friendliness: Choose software with an intuitive interface that is easy for your staff to use.

- Security Features: Prioritize robust security measures to protect your data.

- Vendor Support: Select a vendor with a strong reputation for providing reliable support and maintenance.

- Cost: Balance cost with features and functionality to find a solution that fits your budget.

Frequently Asked Questions (FAQ)

- Q: What is the difference between serialized and lot-based inventory management?

A: Serialized inventory tracks individual items with unique serial numbers, while lot-based tracking groups items with similar characteristics. Serialization offers greater traceability and security. - Q: Is serialized inventory management suitable for all businesses?

A: No, it’s most beneficial for businesses dealing with high-value, easily counterfeited, or regulated goods. Smaller businesses with simpler inventory needs may find it overkill. - Q: How much does serialized inventory management software cost?

A: Costs vary significantly depending on features, scalability, and vendor. Expect a range from subscription-based models to one-time purchases with varying implementation costs. - Q: How long does it take to implement serialized inventory management software?

A: Implementation time depends on the size and complexity of your inventory, the chosen software, and your internal processes. It can range from a few weeks to several months. - Q: What are the potential challenges of implementing serialized inventory management?

A: Challenges include data migration, staff training, integration with existing systems, and potential initial cost investment.

References

While specific software vendors are not named to maintain impartiality, researching reputable providers of Enterprise Resource Planning (ERP) and Warehouse Management System (WMS) software will reveal options with serialized inventory management capabilities. Look for case studies and reviews to inform your decision. Further research into industry-specific regulations (e.g., DSCSA) will provide additional context for your needs.

Call to Action

Investing in serialized inventory management software can significantly improve your business’s efficiency, security, and compliance. Take the next step towards optimizing your inventory management by researching available solutions and contacting a reputable software provider today. Don’t hesitate to reach out for a consultation to determine if serialized inventory management is the right fit for your specific needs.

Implementing serialized inventory management software represents a significant step toward achieving greater control and efficiency within any organization. The benefits extend beyond simple inventory tracking, impacting areas such as loss prevention, quality control, and regulatory compliance. By embracing this technology, businesses can unlock significant improvements in operational effectiveness and gain a competitive edge in today’s dynamic marketplace. The enhanced visibility and detailed tracking capabilities provide valuable data for informed decision-making, leading to improved profitability and sustained growth.

FAQ Guide

What are the common challenges in implementing serialized inventory management software?

Common challenges include the initial cost of implementation, the need for comprehensive data migration, and the potential for integration issues with existing systems. Proper planning and selecting a reputable vendor can mitigate these challenges.

How does serialized inventory management software improve security?

It enhances security by providing a detailed audit trail of every item, making it easier to detect and prevent theft or loss. The ability to track individual products also aids in combating counterfeiting.

What industries benefit most from serialized inventory management software?

Industries with high-value goods, pharmaceuticals, electronics, and luxury items benefit significantly. Any industry requiring precise tracking of individual products can leverage its advantages.

Is serialized inventory management software scalable?

Yes, most reputable software solutions are designed to scale with your business needs, accommodating growth in inventory and operational complexity.