Manufacturing work order software is revolutionizing how factories and production facilities manage their operations. Efficiently tracking work orders, managing resources, and monitoring progress are crucial for maintaining productivity and profitability. This software offers a centralized system to consolidate information, reducing errors and streamlining communication between different departments, from engineering and planning to production and quality control. This ultimately leads to improved efficiency, reduced waste, and enhanced overall manufacturing processes.

The benefits extend beyond simple task management. Modern systems often integrate with other business software, creating a seamless flow of data across the entire organization. This integration can provide real-time insights into production performance, allowing for proactive adjustments and optimized resource allocation. Furthermore, the ability to generate detailed reports provides valuable data for analysis and continuous improvement initiatives.

In today’s competitive manufacturing landscape, efficiency and accuracy are paramount. Manufacturing work order software offers a powerful solution to optimize production processes, reduce errors, and ultimately boost profitability. This comprehensive guide delves into the intricacies of this crucial technology, exploring its features, benefits, and implementation considerations. We’ll also address frequently asked questions to provide a complete understanding of how manufacturing work order software can transform your business.

Understanding Manufacturing Work Order Software

Manufacturing work order software is a sophisticated system designed to manage the entire lifecycle of a manufacturing order, from initial request to final delivery. It acts as a central hub, integrating various aspects of the production process, including planning, scheduling, tracking, and reporting. This integrated approach minimizes data silos and promotes seamless communication across different departments.

Key Features of Effective Manufacturing Work Order Software

- Order Creation and Management: Easily create, modify, and track work orders with detailed specifications, including materials, labor, and equipment requirements. This often includes features for creating custom work order templates to streamline repetitive tasks.

- Inventory Management: Integrate with your inventory system to ensure accurate material tracking, automatic alerts for low stock levels, and efficient allocation of resources. This prevents production delays due to material shortages.

- Scheduling and Planning: Optimize production schedules based on capacity, material availability, and deadlines. Advanced systems utilize algorithms to minimize lead times and maximize throughput.

- Real-time Tracking and Monitoring: Monitor the progress of work orders in real-time, identifying bottlenecks and potential delays early on. This allows for proactive intervention and prevents costly disruptions.

- Labor Management: Track employee time and productivity, assign tasks, and monitor performance. This data provides valuable insights for improving efficiency and optimizing workforce allocation.

- Quality Control: Integrate quality control checkpoints into the work order process, ensuring adherence to standards and minimizing defects. This often involves features for recording inspection results and generating quality reports.

- Reporting and Analytics: Generate comprehensive reports on production efficiency, material costs, labor costs, and other key metrics. Data-driven insights facilitate continuous improvement and informed decision-making.

- Integration with Other Systems: Seamless integration with ERP (Enterprise Resource Planning) systems, CRM (Customer Relationship Management) systems, and other relevant software enhances overall efficiency and data consistency. This creates a unified view of your business operations.

Benefits of Implementing Manufacturing Work Order Software

The benefits of implementing a robust manufacturing work order system extend far beyond improved organization. They directly impact your bottom line and contribute to sustainable growth.

Increased Efficiency and Productivity

By automating repetitive tasks and streamlining workflows, manufacturing work order software significantly boosts efficiency and productivity. Real-time tracking allows for quicker identification and resolution of issues, minimizing downtime and maximizing output.

Reduced Costs

Improved efficiency translates to reduced operational costs. Accurate inventory management minimizes waste, while optimized scheduling reduces labor costs and material expenses. Early detection of potential problems prevents costly delays and rework.

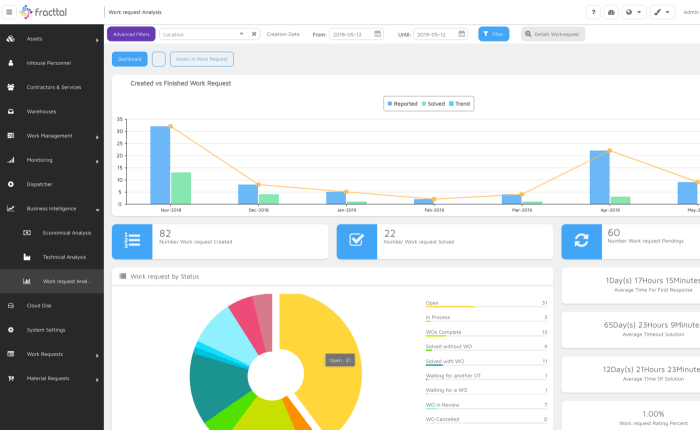

Source: clickup.com

Improved Accuracy and Quality

Automated processes and integrated quality control checkpoints minimize errors and improve the overall quality of your products. This leads to higher customer satisfaction and reduced returns.

Better Inventory Control

Real-time inventory tracking provides a clear picture of material availability, preventing production delays due to shortages and minimizing waste due to overstocking. This enhances supply chain management.

Enhanced Collaboration and Communication

Centralized information sharing fosters better collaboration between different departments, improving communication and reducing misunderstandings. This streamlined communication leads to smoother operations.

Data-Driven Decision Making

Comprehensive reporting and analytics capabilities provide valuable insights into your operations, allowing for data-driven decision-making and continuous improvement. This allows for proactive adjustments to optimize processes.

Choosing the Right Manufacturing Work Order Software

Selecting the right software involves careful consideration of your specific needs and requirements. Factors to consider include:

- Scalability: Choose software that can adapt to your future growth and changing needs.

- Integration capabilities: Ensure seamless integration with your existing systems.

- User-friendliness: Opt for intuitive software that is easy for your team to learn and use.

- Customization options: Consider the level of customization needed to fit your unique processes.

- Cost and support: Evaluate the total cost of ownership, including licensing fees, implementation costs, and ongoing support.

Implementation and Training

Successful implementation requires careful planning and execution. This includes:

- Data migration: Transferring existing data to the new system accurately and efficiently.

- User training: Providing comprehensive training to your team to ensure proper utilization of the software.

- Ongoing support: Establishing a system for ongoing support and maintenance.

Frequently Asked Questions (FAQ)

- Q: What is the cost of manufacturing work order software? A: The cost varies widely depending on the features, scalability, and vendor. Expect a range from affordable cloud-based solutions to more expensive enterprise-level systems.

- Q: How long does it take to implement manufacturing work order software? A: Implementation time depends on the complexity of your operations and the chosen software. It can range from a few weeks to several months.

- Q: What are the key metrics to track after implementing the software? A: Key metrics include production efficiency, lead times, inventory turnover, defect rates, and overall order fulfillment time.

- Q: Can the software integrate with my existing ERP system? A: Many manufacturing work order software solutions offer seamless integration with popular ERP systems. This is a crucial factor to consider during selection.

- Q: What type of training is provided? A: Most vendors offer comprehensive training programs, including online tutorials, webinars, and on-site training.

Conclusion

Manufacturing work order software is a vital tool for modern manufacturers seeking to optimize their operations and gain a competitive edge. By streamlining workflows, improving accuracy, and providing valuable data-driven insights, this technology empowers businesses to enhance efficiency, reduce costs, and ultimately achieve greater profitability. Investing in the right software is a strategic move towards a more efficient and successful future.

References

While specific software recommendations are avoided to maintain objectivity, reputable sources for researching manufacturing software include Gartner, Forrester, and various industry publications like Manufacturing.net and IndustryWeek. Searching for “best manufacturing work order software” on these platforms will provide relevant comparisons and reviews.

Call to Action

Ready to transform your manufacturing processes? Contact us today for a consultation to discuss your specific needs and explore how manufacturing work order software can benefit your business.

In conclusion, implementing manufacturing work order software offers a significant opportunity for businesses to enhance their operational efficiency and gain a competitive edge. By centralizing information, streamlining workflows, and providing valuable data-driven insights, these systems empower manufacturers to optimize their processes, reduce costs, and ultimately improve the quality of their products. The transition may require initial investment and training, but the long-term benefits far outweigh the initial hurdles, leading to a more streamlined, efficient, and profitable manufacturing operation.

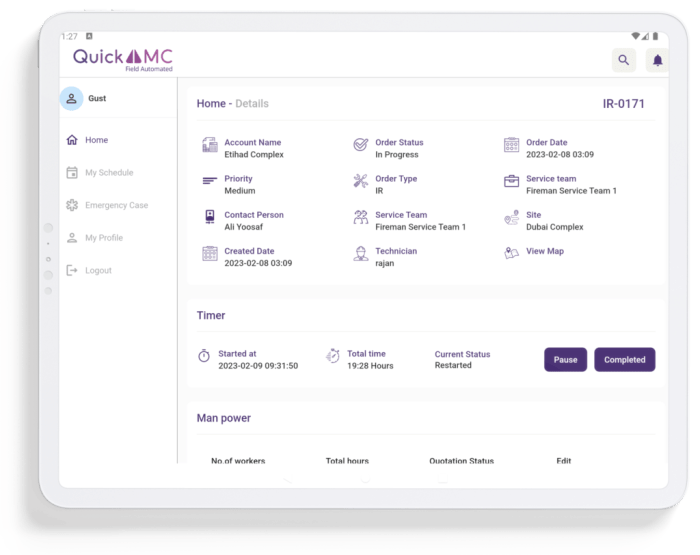

Source: quickamc.com

FAQ Corner

What are the key features to look for in manufacturing work order software?

Key features include robust scheduling capabilities, real-time tracking of progress, inventory management integration, reporting and analytics dashboards, and seamless integration with other business systems.

How much does manufacturing work order software typically cost?

Costs vary greatly depending on the size of the business, the specific features required, and whether the software is cloud-based or on-premise. Pricing models can range from subscription-based fees to one-time license purchases.

What type of training is needed to use manufacturing work order software?

Training needs vary depending on the complexity of the software and the users’ technical skills. Many vendors offer online tutorials, training videos, and on-site support to facilitate a smooth transition.

Can manufacturing work order software integrate with existing ERP systems?

Many modern systems offer integration capabilities with popular ERP systems, allowing for seamless data flow and a unified view of business operations. It’s crucial to check for compatibility before purchasing.